- SIMPLIFY 3D TRIAL FOR FREE

- SIMPLIFY 3D TRIAL FOR MAC

- SIMPLIFY 3D TRIAL INSTALL

- SIMPLIFY 3D TRIAL 64 BIT

- SIMPLIFY 3D TRIAL TRIAL

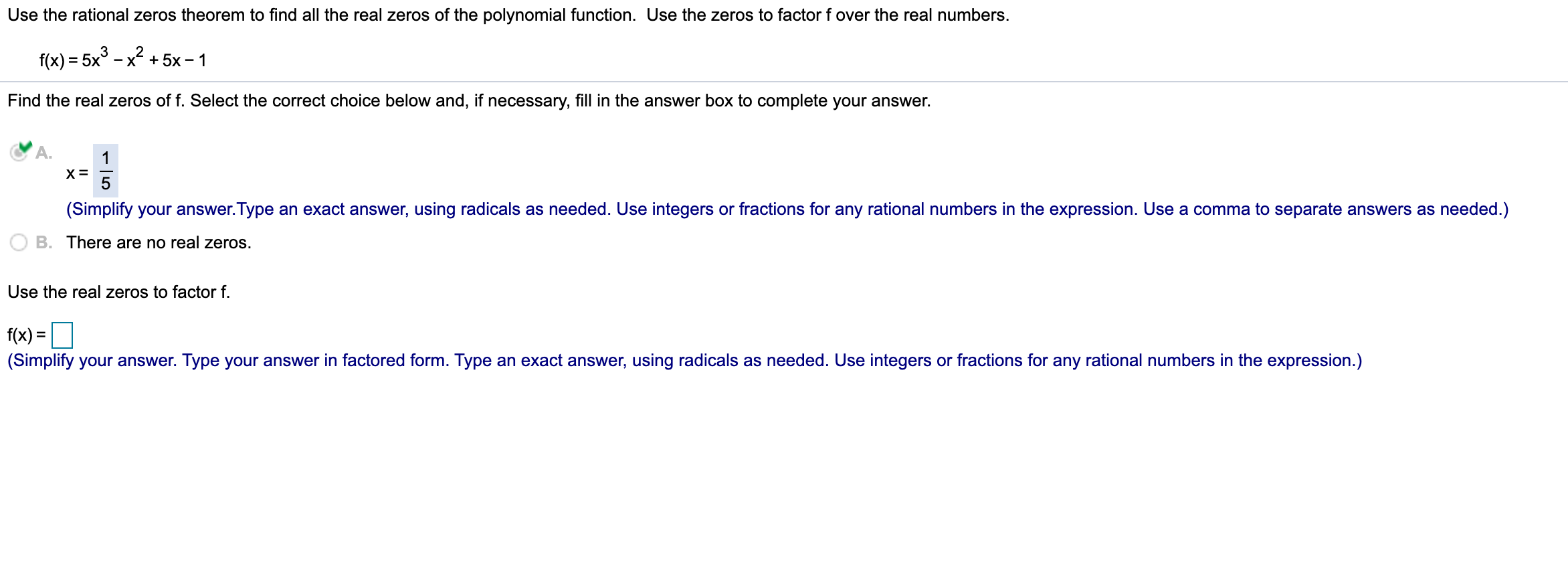

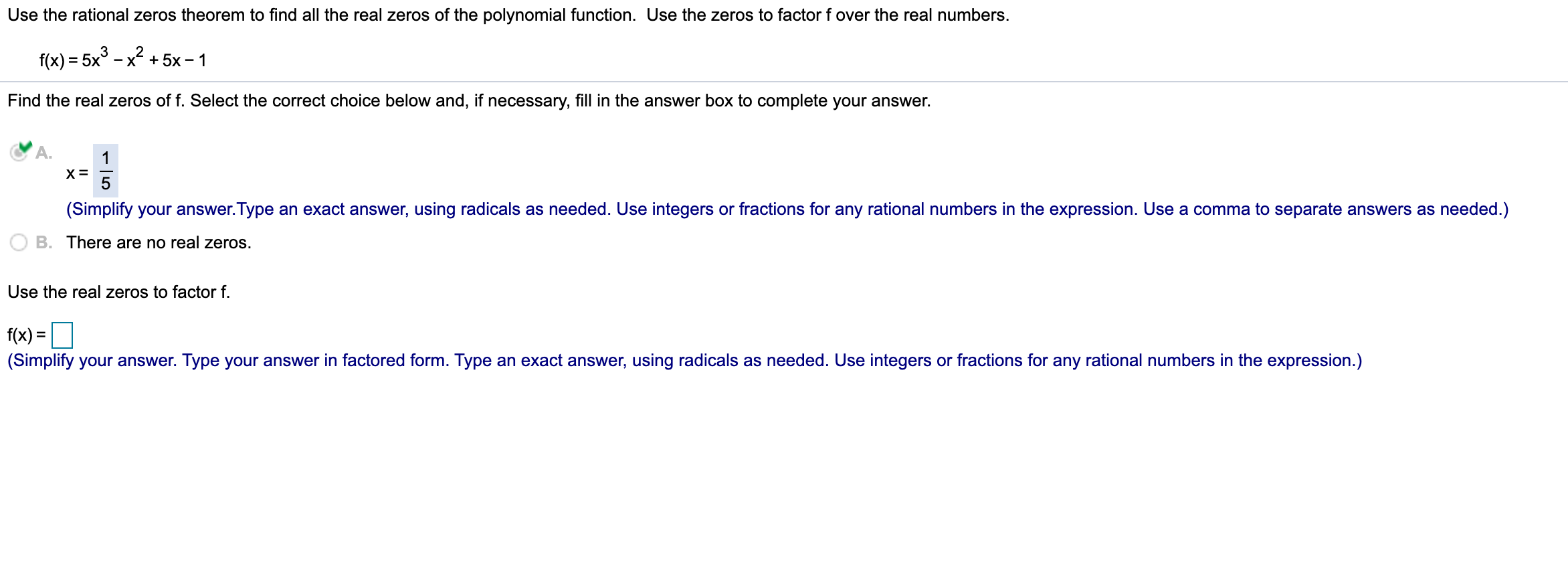

I download the fusion model from the instructable and upload it to Fusion. He has 3 different models that correspond to the quality settings on the Objet DLP printer, but any one of these will do for our purposes. 002” (.05mm) and a female box that fits over them. It has a Fusion model with a row of male gauges that step down in width by. John Edmark’s Objet 3D Printer Fit Tests instructable is a great way to test tolerances for your design. If you want to use free software, Cura is a good alternative: It costs $150, but the results are second to none. A browser-only version of the app is currently in beta, follow this link to sign up and use it for free:įor the remaining lessons I'll be using Simplify 3D because it has superior support structures.

SIMPLIFY 3D TRIAL 64 BIT

If you don't have a Mac or PC with a 64 bit processor, Fusion won't work on your machine.

Select the "I accept Terms and Conditions" checkbox and click Submit. Sign up as a Student or Educator (Free) or Sign up as a Start-Up or Enthusiast (Free).

SIMPLIFY 3D TRIAL FOR FREE

In the next dialog box, select "Register for Free Use". SIMPLIFY 3D TRIAL TRIAL

When you open Fusion, select the Trial Counter in the upper toolbar. SIMPLIFY 3D TRIAL INSTALL

Install and setup a free Autodesk ID account. Enter your email and download the free trial. Follow the link to download Fusion (don't use the App Store on Mac). SIMPLIFY 3D TRIAL FOR MAC

FUSION 360 INSTALLATION FOR MAC / PC WITH 64 BIT PROCESSOR The F3D file attached here is a Fusion file that you can open and edit yourself. The STL file attached here is ready to print- you can just bring it into your slicer as-is and print it out. What to do!? How do you decide what dimensions to use to make sure your parts fit together properly? It's actually really easy- all you have to do is print a copy of John Edmark's model from his Objet 3D Printer Fit Tests instructable and try it out on your printer with your slicer.

A lower tolerance (0.15mm+) will ensure that parts can fit together, but if the tolerance is too low, the parts will fit loosely, and assemblies will be imprecise.

A higher tolerance (0.00mm - 0.05mm) can make for a tight fit, but depending on the performance of the 3D printer and slicing software, a tolerance that's too high will mean that parts can't be fit together at all. There are always variations on the actual dimensions of printed objects, and you need a good understanding of the limits of the particular technology you're using if you want to be able to anticipate your results. Tolerance is a very important factor in 3D printing because (like any kind of manufacturing or fabricating), nothing is ever created perfectly. This would be considered a "low tolerance" in the world of 3D printed parts. The slightly smaller peg will allow it to move freely inside of the hole. The peg will have to be forced into the hole and will probably break the part.Ī tolerance of 0.50 would mean that a 5mm hole would fit with a 4.5mm peg. For example, if your tolerance is 0.00, then you would design a 5mm hole to fit a 5mm peg- with a desktop FDM printer, this won't work because the tolerance is too high. Think of the tolerance as the allowable limit of variation on the dimensions of parts that have to connect to other parts. In the Bottle Lock lesson, we're going to make a model that has two halves with a built-in hinge that will allow the two parts to move in a clamping action.īefore we go too far in designing all the features we'll need to combine the separate parts of a complex model (tabs, slots, posts, holes, etc.), we need to print a test object so we can see how precise we have to as we are designing the model.Īnytime you 3D print an object that's designed to interface with another object (whether printed, manufactured, or fabricated by another method), there is an important factor to consider: Tolerance. This will mean working with moving parts and assemblies. With a simple project completed, it's time to learn to make objects that are more complex.

A higher tolerance (0.00mm - 0.05mm) can make for a tight fit, but depending on the performance of the 3D printer and slicing software, a tolerance that's too high will mean that parts can't be fit together at all. There are always variations on the actual dimensions of printed objects, and you need a good understanding of the limits of the particular technology you're using if you want to be able to anticipate your results. Tolerance is a very important factor in 3D printing because (like any kind of manufacturing or fabricating), nothing is ever created perfectly. This would be considered a "low tolerance" in the world of 3D printed parts. The slightly smaller peg will allow it to move freely inside of the hole. The peg will have to be forced into the hole and will probably break the part.Ī tolerance of 0.50 would mean that a 5mm hole would fit with a 4.5mm peg. For example, if your tolerance is 0.00, then you would design a 5mm hole to fit a 5mm peg- with a desktop FDM printer, this won't work because the tolerance is too high. Think of the tolerance as the allowable limit of variation on the dimensions of parts that have to connect to other parts. In the Bottle Lock lesson, we're going to make a model that has two halves with a built-in hinge that will allow the two parts to move in a clamping action.īefore we go too far in designing all the features we'll need to combine the separate parts of a complex model (tabs, slots, posts, holes, etc.), we need to print a test object so we can see how precise we have to as we are designing the model.Īnytime you 3D print an object that's designed to interface with another object (whether printed, manufactured, or fabricated by another method), there is an important factor to consider: Tolerance. This will mean working with moving parts and assemblies. With a simple project completed, it's time to learn to make objects that are more complex.

0 kommentar(er)

0 kommentar(er)